Electric mobility is no longer a vision of the future—it is a tangible and accelerating reality. However, to make this transition truly sustainable, it is not enough to simply replace internal combustion engines with lithium batteries. What’s needed is a deeper transformation: a complete redesign of the battery lifecycle—from production to end-of-life—based on the principles of the circular economy. This is the very direction being pursued by the new European regulations and by the most forward-thinking companies in the sector.

With the entry into force of EU Regulation 2023/1542, the European Union has established a new regulatory framework that redefines every phase of a battery’s life: from eco-design and traceability to recycling, second-life applications, and corporate environmental and social responsibility. It represents a major turning point for the entire value chain, particularly for companies like Archimede Energia, which develop high-performance lithium batteries designed to integrate seamlessly into advanced electric mobility systems, energy storage applications, and industrial operations.

EU Regulation 2023/1542: a new standard for battery sustainability

Since August 18, 2023, EU Regulation 2023/1542 has officially replaced Directive 2006/66/EC. The new regulation introduces significant changes, including:

- Battery Passport: All industrial and electric vehicle (EV) batteries must include a QR code that enables tracking of their composition, origin, and remaining life.

- Carbon Footprint Calculation: Companies will be required to measure and declare the carbon emissions associated with every phase of a battery’s lifecycle. Emission limits will be introduced at a later stage.

- Mandatory Due Diligence: Starting in 2025, manufacturers must implement measures to identify, monitor, and mitigate environmental and social risks linked to the sourcing of raw materials.

- Recycling of Critical Raw Materials: At least 50% of the lithium in a battery must be recovered by 2027, through specialized collection and recycling centers.

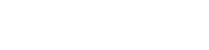

Compliance timeline: key dates and regulatory deadlines

To allow manufacturers and supply chain operators to adapt progressively, the EU regulation defines a phased implementation of its obligations. Below is a summary of the key milestones:

Battery categories covered by the regulation

The regulation applies to all types of batteries, regardless of their shape, weight, composition, or intended use. The main categories include:

- Portable batteries: sealed, weighing ≤ 5 kg, intended for general-purpose applications.

- LMT batteries (Light Means of Transport): used in electric bikes, scooters, and similar vehicles; sealed and weighing ≤ 25 kg.

- SLI batteries: designed for starting, lighting, and ignition functions in vehicles.

- EV batteries (Electric Vehicles): specifically developed to provide traction power to hybrid or fully electric vehicles.

- Industrial batteries: weighing more than 5 kg and not intended for automotive or LMT use.

- Embedded batteries: batteries incorporated into or added to other products, such as electrical devices, industrial machinery, and lifting equipment.

In cases where a battery falls into multiple categories, the most stringent requirements will apply.

CE marking, traceability, and labelling

Starting from August 18, 2024, all batteries placed on the EU market must carry the CE mark, and their labels must include:

- Nominal capacity and expected service life

- Chemical composition

- Symbols indicating proper disposal and recycling

From 2026, this information must also be clearly visible on external labels. As of 2027, it will be mandatory to include a QR code that gives digital access to complete technical specifications.

Digital battery passport: transparency and data via QR Code

As of February 18, 2027, industrial batteries > 2 kWhEV batteries, and LMT batteries must be equipped with a digital battery passport containing:

- Manufacturer’s name, brand, and unique identifier

- Battery type and model

- Chemical composition and any hazardous substances present

- Percentage of recycled raw materials used

- Date of manufacture and market placement

- State of Health (SoH) and remaining lifespan (via Battery Management System – BMS)

- Possibility of disassembly, repair, and reuse

- Instructions for end-of-life handling and recycling

The passport will be accessible via a QR code, with partial data visibility restricted to authorized operators. Technical implementation guidelines will be published by August 2025.

This data will serve not only traceability purposes, but also support predictive maintenance, second-life use, and environmental impact assessments.

Mandatory “crossed-out bin” symbol

To ensure correct end-of-life treatment, the regulation mandates the display of the “crossed-out wheeled bin” symbol on all batteries, indicating:

- Prohibition of disposal in mixed municipal waste

- Requirement for collection at authorized recycling centers

- Classification as WEEE (Waste Electrical and Electronic Equipment)

This symbol must be clearly visible, indelible, and legible, and applied directly to the battery. If not feasible due to physical constraints, it must appear on the packaging or accompanying documentation.

Performance, durability, and disassembly requirements

To promote sustainable design and reduce waste, the regulation introduces minimum performance and durability standards:

- From August 18, 2027 for rechargeable industrial batteries > 2 kWh

- From August 18, 2028 for portable batteries

February 18, 2027, batteries must be designed to allow safe disassembly and replacement by professional operators, facilitating reuse and end-of-life material recovery.

Recycled material targets: binding objectives by 2028

From August 18, 2028, all industrial and EV batteries will be required to contain minimum levels of recycled materials:

- Cobalt: ≥ 16%

- Nickel: ≥ 6%

- Lithium: ≥ 6%

- Lead: ≥ 85%

This requirement supports the development of a truly circular economy and encourages the use of advanced raw material recovery technologies.

Safety and limits on hazardous substances

To protect human health and the environment, stricter thresholds for heavy metals will apply starting August 18, 2024:

- Mercury: max 0.0005%

- Cadmium: max 0.002%

- Lead (in portable batteries): max 0.01%

Furthermore, applications such as Stationary Battery Energy Storage Systems (SBESS) will require certified safety testing to ensure compliance with fire and electrical safety standards.

Supply chain due diligence: environmental and social responsibility

One of the cornerstones of the new EU Battery Regulation is the implementation of a formal environmental and social due diligence system throughout the battery supply chain. The objective is to ensure that critical raw materials (such as cobalt, lithium, nickel, and graphite) are traceable, responsibly sourced, and compliant with international standards.

The key obligations include:

- Mapping of suppliers across the entire supply chain

- Management of environmental and human rights risks, including prevention and mitigation measures

- Compliance with OECD and UN international guidelines

- Audits and controls conducted by accredited third-party bodies

- Periodic public reporting on the implementation of adopted measures

Initially scheduled to take effect on August 18, 2025, these obligations have been officially postponed to August 18, 2027. The deferral was approved on June 19, 2025, by Coreper (the Committee of Permanent Representatives to the EU Council), in order to provide businesses with more time to adapt.

What does the suspension include?

- A two-year postponement of the entire due diligence package, including public reporting and independent third-party verification.

- More time for third-party bodies responsible for compliance checks to complete their accreditation processes, which currently lack a standardized EU framework.

- Advance guidance from the European Commission, which has committed to publishing the official due diligence guidelines at least one year prior to their enforcement, to support companies in implementing the new requirements.

- Reduced reporting burden: the due diligence compliance report will be required every three years, instead of annually.

This postponement is part of the broader “Omnibus IV” package, introduced to streamline EU legislation and enhance industrial competitiveness. In particular, the deferral is seen as essential to enable a smooth and achievable transition to higher sustainability standards—especially for European battery manufacturers and exporters.

Nonetheless, it marks a pivotal step forward: improving transparency in the sourcing of raw materials contributes meaningfully to building a more ethical and sustainable supply chain, particularly in a global context where many critical materials originate from geopolitically unstable or exploitative regions.

Lithium battery recycling and collection: 2027 targets

The new regulation sets clear requirements for efficient end-of-life battery management, including:

- Free take-back service for end users (0:1 system)

- Obligation to establish a widespread, accessible collection network

Minimum recycling efficiency targets by December 31, 2027:

- Cobalt, copper, nickel, lead: ≥ 90%

- Lithium: ≥ 50%

In addition, specific collection rate targets are set for:

- Portable batteries: 73% by 2030

- LMT batteries: 61% by 2031

The circular economy for batteries: how it works in practice

Applying circular economy principles to lithium batteries means maximizing their value throughout their entire lifecycle, even after their initial use. The three core pillars are:

1. Life Cycle Assessment (LCA)

Assessing the overall environmental impact of a battery from cradle to grave helps identify inefficiencies and optimize production, usage, and recovery processes.

2. Second-Life Applications

Used EV batteries can be repurposed as stationary energy storage systems (e.g., for photovoltaic systems), reducing environmental impact by up to 70% compared to producing new batteries.

3. Raw Material Recovery

It is now technically possible to recover over 90% of the materials in a lithium battery. However, this requires targeted investments in recycling infrastructure and the creation of dedicated recycling gigafactories, such as those promoted under IPCEI (Important Projects of Common European Interest) initiatives.

Archimede Energia’s role: innovation meets responsibility

The lithium battery market is expanding rapidly. According to McKinsey, by 2030 the volume of end-of-life batteries will match global demand for solar energy storage. It is therefore crucial to develop scalable solutions for reuse, recycling, and full lifecycle traceability.

Archimede Energia, through its participation in initiatives such as Haiki Cobat, is actively supporting this transformation. Our goal is to contribute to building a responsible and resilient supply chain, ready to meet the environmental and industrial challenges of the coming years.

A circular economy is not just possible—it’s already underway

The energy transition requires more than just technological innovation—it demands a revolution in production and consumption models.

If designed and managed responsibly, lithium batteries can become a strategic asset rather than an environmental liability.

Thanks to the new EU regulation and the commitment of forward-looking companies, the future of batteries will be increasingly:

- Transparent

- Traceable

- Recyclable

- Sustainable

Want to learn more about Archimede Energia’s lithium battery solutions and regulatory compliance?

Contact us for a personalized technical consultation.