Runtime, Energy Consumption Calculation, and Operating Cost Savings

Runtime is one of the most decisive factors when choosing a LED light tower powered by batteries. On construction sites, during evening events, or in industrial environments where a grid connection is not always available, the ability to operate continuously and reliably makes the difference between an efficient system and one that requires frequent intervention.

Today, thanks to lithium batteries, it is possible not only to extend operating hours, but also to significantly reduce operating costs and environmental impact compared to traditional solutions.

In this in-depth guide, we analyze what determines the runtime of a light tower, how to calculate it correctly, and how to estimate long-term energy and cost savings.

Are you considering a battery-powered light tower for a construction site or temporary service?

We can help you estimate real runtime, energy consumption, and operating savings for your specific application.

Why Runtime Is a Strategic Factor

A light tower with limited autonomy can:

- interrupt operational continuity on construction sites or service areas;

- generate additional costs due to frequent recharging or auxiliary power systems;

- compromise the safety of people and infrastructure during nighttime operations.

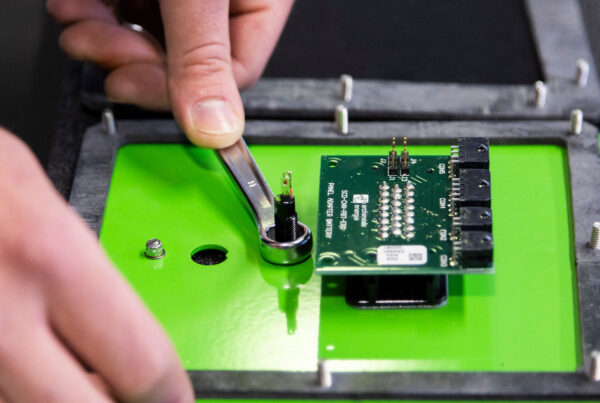

Lithium batteries—particularly those using LiFePO₄ technology—allow significantly longer operating times, reduced system weight, and consistent performance over time, even under intensive duty cycles.

What Determines the Runtime of a LED Light Tower

Runtime is not a fixed value, but the result of the interaction between several technical and environmental factors.

1. Battery Capacity (Ah)

Battery capacity, expressed in ampere-hours, indicates how much energy can be stored.

The higher the capacity, the greater the potential runtime.

2. System Voltage (V)

Voltage multiplies battery capacity.

Available energy is calculated using the formula:

Available energy (Wh) = Capacity (Ah) × Voltage (V)

48 V DC systems are now widely adopted in lithium battery applications because they enable more efficient energy management and lower electrical losses.

3. Total Installed Power (W)

Actual consumption depends on the total power of the lighting system.

Typical configurations with four LED floodlights can range from less than 500 W to more than 1,200 W total.

With the same battery capacity, increasing installed power proportionally reduces runtime.

4. System Efficiency

Inverters, LED drivers, cabling, and battery management systems affect overall efficiency.

A realistic efficiency range is generally between 85% and 90%.

5. Environmental Conditions

Extreme temperatures, humidity, and irregular load cycles can influence performance.

Lithium batteries equipped with advanced BMS systems can partially manage and compensate for these variables.

Every construction site and operational project has specific requirements.

The runtime that truly matters is the one calculated using your real operating data.

If you want a personalized consultation, speak with our technical team.

Practical Example of Runtime Calculation

Let us consider a lithium battery with:

- Capacity: 111 Ah

- Voltage: 48 V

Available energy:

111 × 48 = 5,328 Wh

With a lighting configuration totaling 460 W:

Theoretical runtime:

5,328 / 460 ≈ 11.5 hours

Applying an efficiency factor of 85%:

Actual runtime ≈ 9–10 hours

By reducing lighting power or increasing battery capacity, runtime increases proportionally.

Would you like to know how many real operating hours a light tower can provide in your specific use case?

Enter your data and receive a personalized runtime estimate.

Runtime and Lighting Configurations

What matters is not only the power of each floodlight, but the total system load.

Example configurations:

4 × 115 W → 460 W total

4 × 250 W → 1,000 W total

4 × 300 W → 1,200 W total

The same platform can deliver very different runtimes depending on the required lighting intensity.

In many operational scenarios, working at reduced power allows a significant increase in operating hours without compromising lighting effectiveness.

From Runtime Calculation to Operating Cost Savings

Beyond runtime, it is essential to evaluate the total operating cost of a lithium battery light tower compared with traditional solutions.

An effective estimate considers:

- daily or weekly operating hours;

- total duration of the usage period;

- LED system energy consumption;

- recharging costs;

- reduction in maintenance activities.

Integration of the Simulation Tool

Calculate Runtime and Savings for Your Light Tower

Enter power, operating hours, and system configuration to obtain a realistic estimate of runtime and operating costs.

Autonomy and Savings Calculator

This tool allows you to estimate the operating autonomy of a battery-powered light tower and the economic savings compared to a traditional solution, based on real usage parameters.

Battery data

Lighting

Usage

Costs

Conclusion

The runtime of a lithium battery light tower is not an absolute value, but the result of a balance between battery capacity, system voltage, installed power, and overall efficiency.

Combining operating-hour calculations with an accurate estimate of operating costs enables data-driven decisions, avoiding oversized systems or economically inefficient solutions.

If you are evaluating a purchase or rental, a technical simulation supported by specialized consultation is the most effective way to select the solution that truly fits your operational needs.