The use of lithium-ion batteries is steadily growing due to their high energy density and long service life. However, when these technologies are applied in environments classified as explosion risk areas (Ex Zones), safety issues become critical.

Risks associated with the use of lithium batteries

In fault conditions—such as internal short circuits, overcharging, deep discharging, or overheating—lithium-ion batteries can undergo uncontrolled exothermic reactions (thermal runaway), releasing toxic and flammable gases or even catching fire. In an explosive atmosphere, even a minor malfunction can escalate into a catastrophic event.

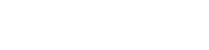

For this reason, it is essential to equip both the battery and the Battery Management System (BMS) with certified protection systems compliant with ATEX/IECEx regulations.

Main protection solutions

IEC/EN 60079 standards outline various protection methods for electrical equipment used in hazardous (Ex) areas. For lithium batteries, the most commonly considered solutions include:

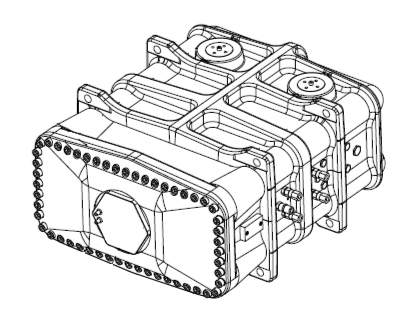

- Ex d – Flameproof Enclosure

This method is designed to contain any internal explosion and prevent it from spreading to the surrounding atmosphere. However, concerns remain regarding surface temperature increases of the enclosure in the event of major internal faults. - Ex o – Liquid Immersion

Immersing the system in a dielectric fluid prevents ignition in explosive atmospheres. Yet, in case of battery failure, the system may not always stay within the temperature limits required by the standard (200°C). - Ex e – Increased Safety

This method avoids the generation of sparks or high temperatures under normal operating conditions. However, it is not designed to contain flames or explosions resulting from internal battery faults.

Spotlight on LFP technology: the safest choice?

Lithium iron phosphate (LFP) batteries are known for their superior thermal stability and lower risk of ignition compared to other lithium-based chemistries. For this reason, they are considered particularly suitable for use in Ex environments. However, it’s important to note that even LFP cells can fail due to manufacturing defects, mechanical damage, or electrical abuse.

Conclusion: safety requires a systemic approach

No protection method alone can completely eliminate risk. To minimize the residual risk of ignition in potentially explosive atmospheres, it is necessary to:

- Integrate certified protection systems (Ex d, Ex o, Ex e) with careful engineering design;

- Evaluate the failure rate of the battery + BMS system;

- Apply a SIL (Safety Integrity Level) analysis to assess the reliability of control systems;

- Continuously monitor temperature, current, and state of charge using advanced BMS technology.

Do you need a safe battery system for an Ex zone application?

Contact us for a technical consultation: our team is available to evaluate your project requirements and help you identify the safest and most effective solution.