The VLQ-173-048-TFI is an advanced energy storage solution engineered to deliver high performance in demanding industrial applications. At Archimede Energia, we build this system using 4 modules with 12 high-density Li-NMC cells, providing 101.1 Wh/kg and a continuous discharge power of up to 8.29 kW. This configuration enables seamless integration into vehicles and machinery with significant energy requirements, enhancing both efficiency and autonomy.

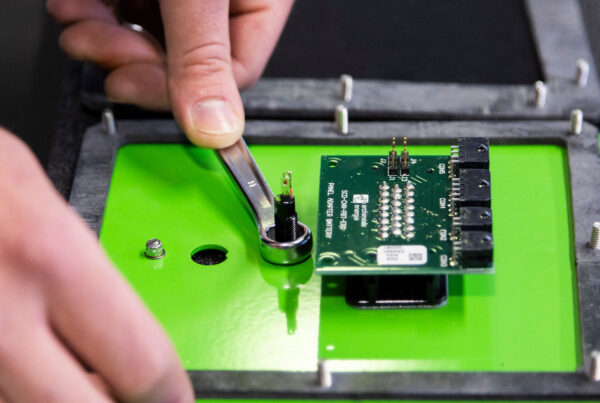

Onboard the VLQ-173-048-TFI, we integrate a proprietary BMS developed in-house by Archimede Energia, designed for continuous monitoring of temperatures, voltages, and currents, while also managing the contactors. The result is a highly safe, reliable, and robust system, perfectly suited for modern industrial electric traction.

Applications: industrial traction and construction site electrification

The VLQ-173-048-TFI battery is used across a wide range of industrial traction equipment, including:

- telescopic handlers

- excavators

- AGVs

- self-propelled industrial vehicles

It is the ideal solution for companies transitioning from internal combustion engines to fully electric systems, aiming to reduce emissions, lower noise levels, and cut operating costs. The electrification of construction machinery is already a reality across advanced job sites, enabling more sustainable, efficient, and low-noise operations without compromising performance or productivity.

At Archimede Energia, we design lithium batteries that can be easily integrated into any type of vehicle, offering clear advantages over traditional battery technologies. Compared to lead–acid solutions, our lithium systems provide:

- higher energy density, delivering more power in less space

- fast charging, even in under 2 hours

- long lifespan, exceeding 3,000 cycles

- zero memory effect

Why choose NMC cells?

Our solutions are based on NMC (Nickel–Manganese–Cobalt) cells, a chemistry widely adopted in the automotive sector thanks to its high energy density and fast-charging capability.

Key advantages of NMC batteries include:

- high energy density

- solid cycle life

- versatile chemistry suitable for various industrial environments

Electrifying construction sites: a real opportunity

The construction industry is among the sectors with the highest environmental impact, with significant CO₂ emissions and noise pollution. Electrifying construction machinery is therefore a strategic lever to meet European sustainability targets and reduce the overall environmental footprint of industrial operations.

Future job sites will be increasingly electric, connected, and sustainable. Lithium batteries — thanks to their safety, durability, and performance — are enabling this transition. As a specialized battery manufacturer, we support engineers and companies in selecting the most suitable solution, customizing each battery system based on the specific requirements of the application.

The modular design of our battery packs allows flexible integration even in off-grid machinery or complex operational environments, ensuring high efficiency and uninterrupted operation.

VLQ-173-048-TFI and TFL version: performance even under high thermal loads

The VLQ-173-048-TFI is also available in the VLQ-173-048-TFL version, equipped with an advanced liquid cooling system with cold plates. This technology ensures extremely precise thermal management and can be easily integrated into existing systems, maintaining the ideal operating temperature even under critical conditions or high thermal loads.

This makes it the perfect choice for applications where endurance, operational continuity, and reliability are essential.

You can find the technical datasheets for both VLQ-173-048-TFI and VLQ-173-048-TFL here.

For any further information, feel free to contact us.